Broughton Lubricants has supplied oils, greases and other products for over 100 years, and our experts have detailed technical knowledge that enables them to provide bespoke product recommendations for any number of applications. Here, we break down some of the primary considerations you should make when choosing a lubricant product yourself. If you have any questions, or would like tailored advice about a specific solution, call us on 03300 555 655.

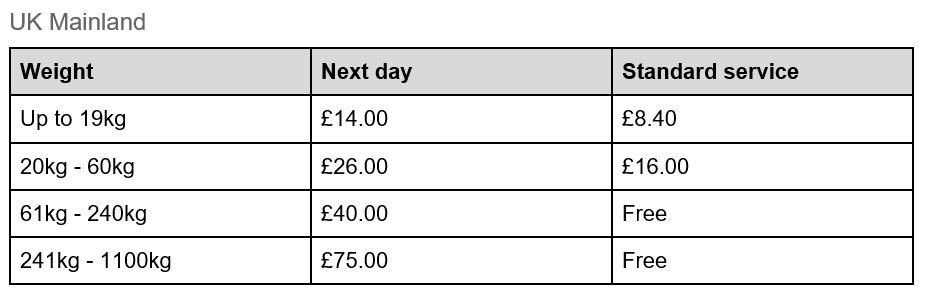

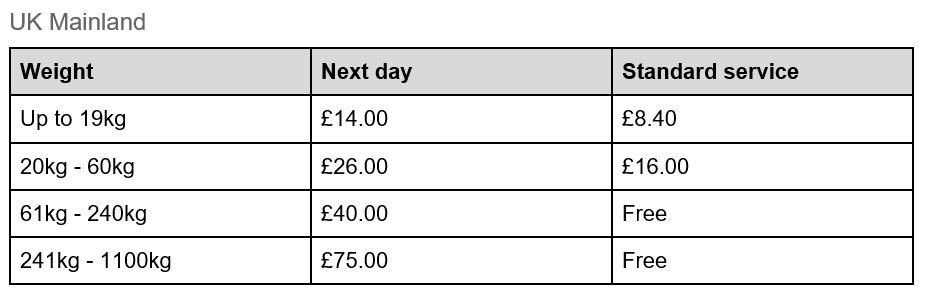

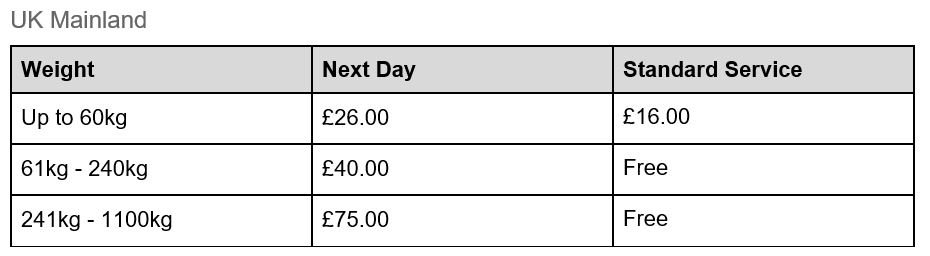

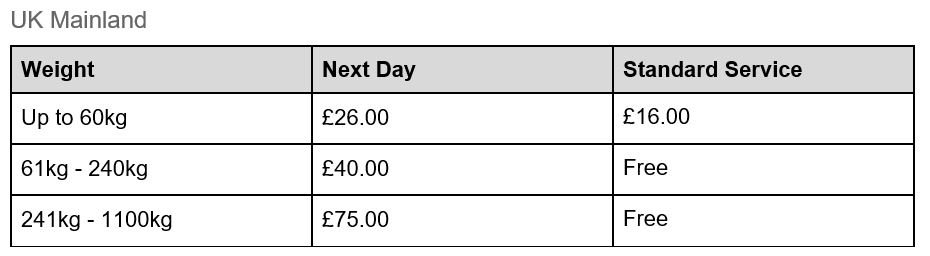

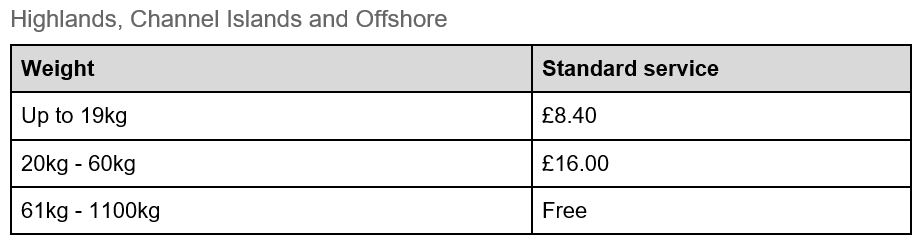

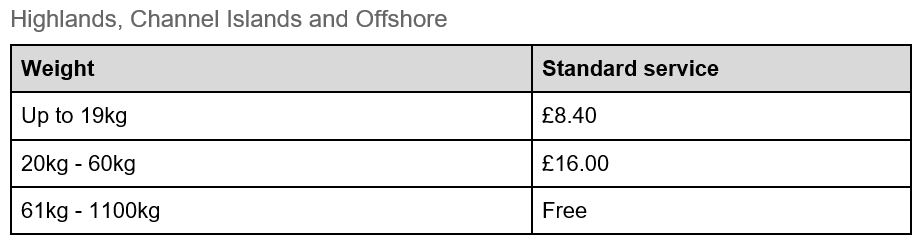

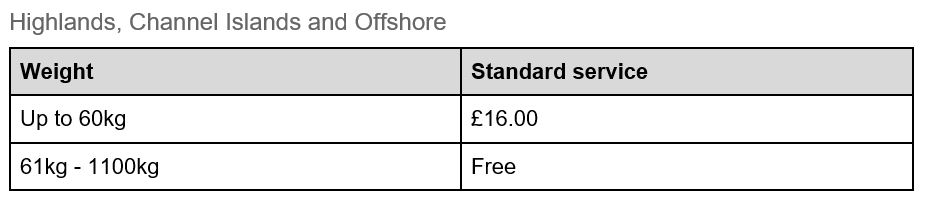

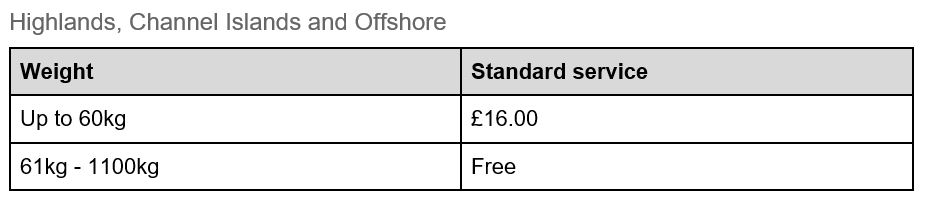

How much do you charge for delivery? Is there a free delivery option?

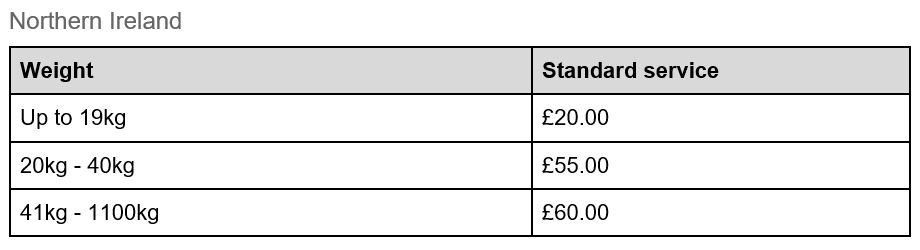

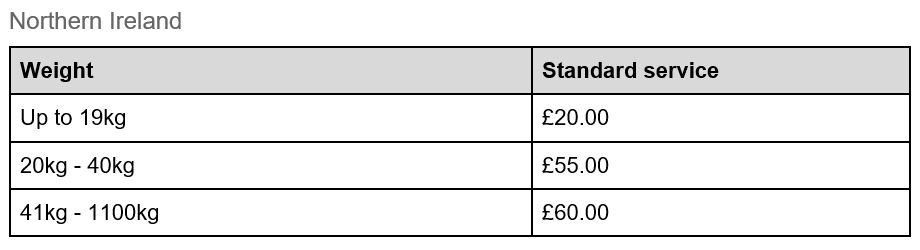

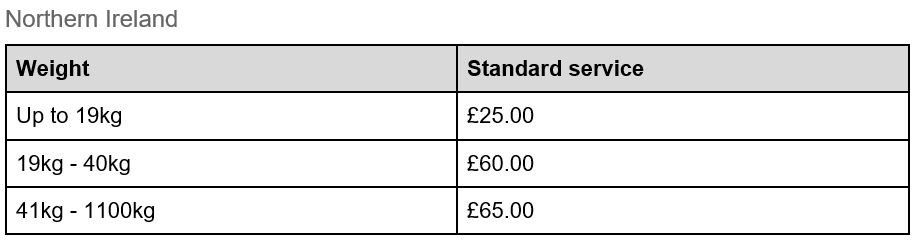

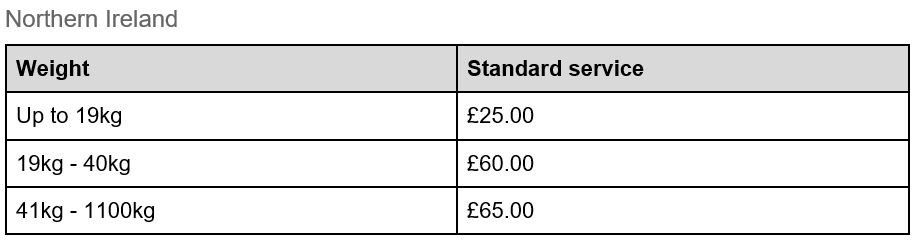

Our standard delivery charges are listed below. Orders weighing more than 60kg qualify for free delivery in England, Scotland and Wales. Unfortunately, we cannot currently offer free delivery in Northern Ireland.

Non-Hazardous Shipping Costs

Hazardous Shipping Costs

What is the lead time for delivery?

Our standard service is 3-4 working days. We also offer next-day delivery to the UK mainland on certain products. You can select this option when checking out online, or when placing an order with the customer services team. Prices for next-day delivery are listed above.

Do you collect empty barrels?

Unfortunately, we do not currently offer this service. Barrels that have been used to store non-hazardous materials can be disposed of as you would any other waste, or they can be reused for storage.

Do you export products outside the UK?

We can export products outside the UK in certain cases. To enquire, send your export requests to [email protected] and we will get back to you.

FAQs about products....

Can you recommend the best lubricant for my application?

Yes, we can. Whether it’s a vehicle, a piece of industrial equipment or a machining application, we can help by recommending the best product for the job. Call us on 03300 555 655 for industrial applications, or 03300 555 109 for automotive applications, to discuss your needs and receive bespoke advice tailored to your requirements.

Does Broughton Lubricants supply environmentally acceptable lubricants?

Yes. If you need a more environmentally-friendly lubricant product, or advice on how to make the best use of the products you are using in order to minimise their environmental impact, call us today. Talk to us about the specifics of your application and we will recommend an environmentally-friendly product, where available, or provide guidance on best practices for more sustainable lubricant use.

What temperature should coolant run at?

Ideally, coolant should operate at less than 30°C. To ensure optimum running temperatures, keep coolant sumps free from swarf contamination and topped up to full.

Why does my coolant smell?

The most common reason why coolant may begin to smell is a microbiological infection. This can cause the fluid to give off hydrogen sulphide during degradation, which emits a rotten egg odour.

This is an important sign that there is a problem with your coolant and you should take urgent action. You should dispose of the coolant and thoroughly clean out the sump with an appropriate product before you replace it.

You can avoid this by undertaking regular maintenance and testing bacteria levels in your coolant frequently. If you are using a coolant that is mixed with water, speak to us about ensuring you have the right concentration of fluids for maximum performance and minimum health risk.

Why do I have a layer of oil on the coolant surface?

The layer of oil that can gather on the surface of a coolant is known as ‘tramp oil’. In most cases, this is normal and can be removed with dedicated devices. It should be removed regularly to prevent the buildup of bacteria within the coolant.

While the presence of tramp oil is to be expected, it can signal a problem in your system if found in combination with other symptoms. In such cases, you should seek further guidance from a Certas application specialist, like those on the technical team at Broughton Lubricants.

What tests must I carry out when using water-soluble metalworking fluids?

If you are using water-soluble metalworking fluids, it is required that you assess and record the following information on a regular basis in order to conform with HSE doctrine:

● Concentration

● pH level

● Bacteria

● Tramp oil

This helps to prevent contamination by bacteria or chemicals. You should ensure that you have appropriate tools and equipment to perform these tests.

The HSE advises that you should perform weekly checks, including concentration by refractometer, pH, and dipslide (microbiological contamination) tests. The frequency of dip slide testing can be reduced accordingly if there is a record indicating good control (around 104 cfu/gram). You can order the items you need to conduct these tests from Broughton Lubricants.

What is a dipslide?

A dipslide is a sterile agar test device used to assess bacterial contamination within water-miscible cutting fluids. You should test bacterial activity in water-soluble cutting fluids regularly in order to comply with advice from the HSE.

Does Broughton Lubricants provide a fluid-testing service?

Yes, we do. One of the benefits of being part of the Certas group is that we can provide more services to our customers, including a fluid-testing service. Depending on your requirements, we can make a service package available via your local sales representative. For more information about our services or to book, contact us via email at [email protected].

Why is my machine tool rusting? Is it a coolant problem?

Corrosion of machine tools using water-miscible cutting fluids can happen for several reasons, and it is best to conduct a fluid test to solve this problem. Areas we would focus on during an initial investigation are product selection, water quality, concentration, contamination, and bacterial activity.

It is important to test concentration and bacteria levels regularly, and if you have not identified any problems in this area then it may be a problem with the product you have chosen to use. Speak to us today for help in diagnosing the problem through our fluid-testing service, or for advice on choosing a suitable cutting fluid.

Can a different soluble metalworking fluid be used to top up the existing one in the machine sump?

In some cases, yes. However, you should check with your supplier first, because many products will be incompatible with each other. This can lead to fluid instability, which can shorten sump life and increase foaming and corrosion. We would usually recommend that sumps are emptied and cleaned before a different metalworking fluid is added. If you would like to top up your existing fluid with another product, call us on 03300 555 655 for advice tailored to your circumstances.

Can different lubricants be mixed?

In some cases, lubricants of similar chemistry can be mixed. However, you should always check with your supplier first to limit the risk of compatibility issues. Mixing different products can reduce the performance of the lubricant, or neutralise certain properties in products that are chemically incompatible, so you should not take a risk if you are unsure.

If a product is described as semi-synthetic, does that mean it doesn’t contain oil ?

The terminology synthetic and semi-synthetic are actually very vague and can vary depending on the product type. Typically, ‘synthetic’ means that a product is made from an alternative base fluid that differs from conventional mineral oil, while ‘semi-synthetic’ products may contain a mixture of mineral oil and an alternative fluid.

Alternative base fluids can include products based on synthetically enhanced hydrocarbons, esters, polymers and other bases, which can result in application benefits. However, it is important to select the most appropriate product for your application rather than simply trying to match the terminology.

Does Broughton Lubricants provide an onsite training service?

Yes, we do. Being part of the Certas group means we have access to a wide variety of resources, including a team of industrial lubricants trainers who can provide onsite training for your staff. Depending on your requirements, you can discuss our service packages with your local sales representative, or email us at [email protected] for further information.

Contact us...

If you need technical support for an industrial or automotive fluid application, or advice on the best product to meet your performance requirements, call us today. You can reach our experts on 03300 555 655 for industrial applications, or 03300 555 109 for automotive applications.